Powder silos (Powder bins) are widely used to hold and discharge flour and other powder materials such as cement and PFA (Pulverized Fuel Ash). Powder is not easy to store and deliver. Steel powder storage silo is your good choice to hold and discharge weighty powder materials. Flour is such kind of powder as the basic ingredient for many food products and stored in silos up to 20 meters high. The filling and emptying of powder silo is often performed by pneumatic systems that transport the stored powder from the large external powder bins and deposit them in smaller holding vessels for further processing. The filling and emptying processes are controlled by reliable level measurement. Pressure monitoring is also required in the pneumatic conveying pipelines. Elevators or conveyors can also be used to handling powder transporting.Powder steel silo is your good choice to hold and discharge weighty powder materials. Powder storage silos have the characteristics of lower cost, shorter construction time and unloading materials easily. The capacity of Shelley steel powder storage silos ranges from 20m³ to 800m³.

Features of Powder Silos

•Perfect sealing assures its efficient working performance.

•Perfect sealing assures its efficient working performance.

•convenient installation.

•Waterproof and moisture-proof.

•Screw connection on inner side, anti-corrosion.

•Can be customized.

•Safe and reliable.

•Unhindered discharge, no blocking.

Components of Powder Silos

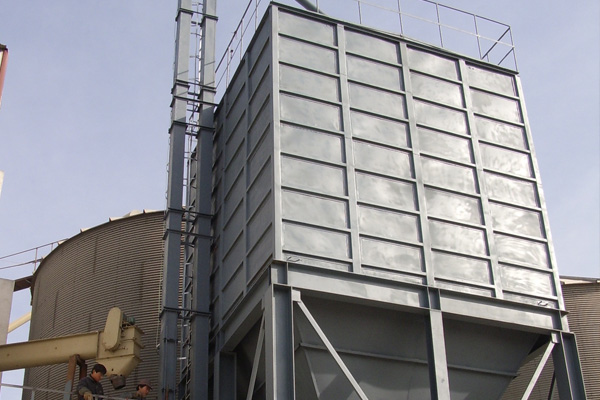

Powder silo (powder bin) includes the silo roof, silo body and silo hopper with legs. Powder silo roof, body, hopper are made of carbon steel, with food grade painting, make sure the safety of the flour; On silo roof, there are flour inlets, safety valve, Vibration filter, Explosion-proof vent, manhole. On silo body, there are ladder, ladder safety guard, level indicator. Powder silo leg is made of round pipe or H beam steel (with normal painting), based on the silo size. According to the customer’s requirement, Powder silo also can be made with stainless steel.

Powder silo can be used indoor or outdoor, round type or square type, no normal specifications. Shelley Engineering can design the flour silo to satisfy the your requirements.

Insulated Powder Silos

Powder or flour product is not easy to store or handle, it should be batch stored in ventilated, cool and dry place, to avoid direct sunlight, prohibited contact with the items that may react, and pay attention to moisture. So the thermal insulated bins are widely used for powder storage. Powder silos can be designed and installed with heat retaining layer to meet your special insulated powder storage requirements. The insulated flour bins are widely used in places where the temperature is large difference between the day and night and humid sites like seaside, they are also widely used in places where the weather are very cold at all seasons which can influence the quality of stored feed pellets. Steel insulated bins will keep the stored powder products in controlled condition. The capacities of our assembly hopper bottom bins can cover the capacities from 10 tons to 10000 tons.

Applications of Powder Silos

Powder silos are widely used in flour mill, flour plant, wheat maize farm, food processing plants or feed production lines, etc. They are also can store cement, powder, lime, gypsum, fly ash, different binder materials, gravel, limestone, sand and different chippers.