Flat bottom silos (also called flat bottom bins, flat bins) are commonly selected steel silos or steel bins to storage bulk grains and other materials. Large volume storage is its typical feature, the storage volume of this type grain storage silo ranges from 39 m³ to 29726 m³. These grain bins are erected on flat or conical concrete foundations for long-term storage of large quantities of grain, seeds, pellets and granular products, etc. All our flat silos or flat bins are designed, manufactured and installed in accordance with D-4097 or ASTM D-3299 standards.

The flat bottom bins are made of high quality 275g/m2, 300g/m2, 350g/m2 hot-dip galvanized steel plates which are rolled into corrugation and made into standard connecting holes. The vertical friction is support by the steel silo stiffeners which are evenly vertically applied in the silos. The connecting screw bolts are served with round galvanized steel washers, the connecting holes are served with age-resistant and water-proof daub belts that are for aviation special purpose.These plates and stiffeners are connected by high-strength screw bolts to keep the flat silo strong and durable. The flat bottom silos are equipped with flat repairing doors, outside ladder and ladder guard rings.

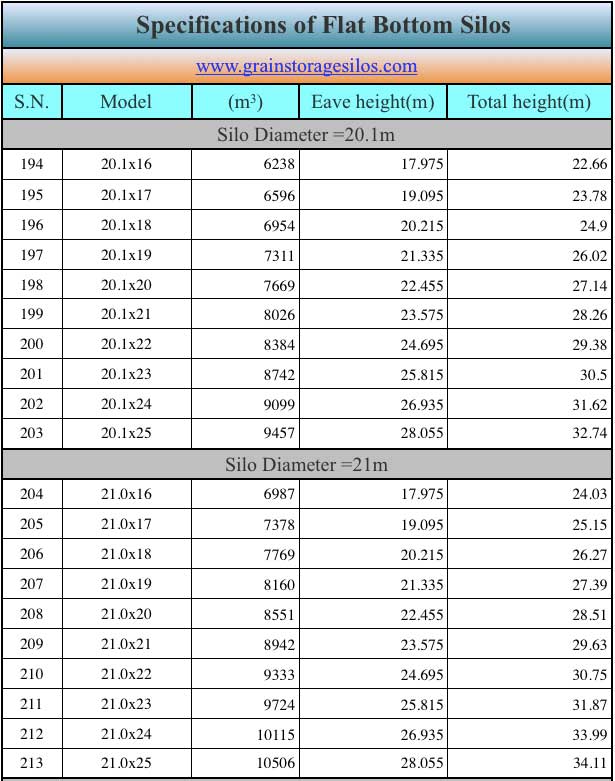

Specifications of Flat Bottom Silos

The volume of Shelley Brand Flat Bottom bin ranges from 30m³ to 1,875m³. The following is part of the specifications. ![]() Please click here to download more hopper silo specifications…

Please click here to download more hopper silo specifications…

Specifications of Flat Bottom Silos

Main Components of Flat Silos

Shelley Brand flat bottom silos are composed of silo roof, manhole, roof handrail, natural vent, inside and outside ladder, ladder safety guard, inside and outside stiffener, silo door, door platform, sweeper, bucket elevators, dust collectors, temperature moisture controller, storage level indicator and storage control system. All of them are integrated into the seamless system to keep you grain storage automatic, safe, efficiently and effectively. All parts are of grain bins made with standard and high quality materials in the strict process and quality control. The following are some of them.

Flat Bottom Insulation Silos

Flat Bottom silos (also called flat bottom bins) can be designed and installed with heat retaining layer to meet your special insulated grain storage demands. Flat bottom insulated bins are effective facilitates to keep the stored products in finest quality and constant temperature from the dewdrop and moldy influence. Insulated storage bins are widely used in places where the temperature is large difference between the day and night and humid sites like seaside, they are also widely used in places where the weather are very cold at all seasons which will influence the seed vitality, steel insulated bins will keep the stored products in controlled condition. Our assembly flat bottom bins with insulation system can cover the capacities from 10 tons to 10000 tons.

Flat Bottom silos (also called flat bottom bins) can be designed and installed with heat retaining layer to meet your special insulated grain storage demands. Flat bottom insulated bins are effective facilitates to keep the stored products in finest quality and constant temperature from the dewdrop and moldy influence. Insulated storage bins are widely used in places where the temperature is large difference between the day and night and humid sites like seaside, they are also widely used in places where the weather are very cold at all seasons which will influence the seed vitality, steel insulated bins will keep the stored products in controlled condition. Our assembly flat bottom bins with insulation system can cover the capacities from 10 tons to 10000 tons.

The thermal insulated bin has three layers, the first layer is the inside layer, it’s also the general silo component parts made with hot-dip galvanized corrugated steel sheets; The second layer is the yellow part, it is the insulating layer made with high-quality thermal insulation rock wool; The third layer is the colorful steel plate or galvanizing sheets.

Production & Application

In recent years, we had invested more than 3,000,000 dollars into our 9,000 square meters state-of-the-art manufacturing grain bin factory. Our modern factory is equipped with the most advanced machines like fiber laser cutting machines, metal steel sheet CNC bending machine and professional welding line, etc , which give us the power to keep high product quality, shorter delivery time and competitive cost to meet the demands of our worldwide customers. Most products had been kept up with the international forefront counterparts. Some of them have enjoyed leading position, especially grain storage controlling software and grain security system.

In recent years, we had invested more than 3,000,000 dollars into our 9,000 square meters state-of-the-art manufacturing grain bin factory. Our modern factory is equipped with the most advanced machines like fiber laser cutting machines, metal steel sheet CNC bending machine and professional welding line, etc , which give us the power to keep high product quality, shorter delivery time and competitive cost to meet the demands of our worldwide customers. Most products had been kept up with the international forefront counterparts. Some of them have enjoyed leading position, especially grain storage controlling software and grain security system.

Flat bottom silos are widely applied for grain storage, animal feed, flour, starch, rice milling factory, grease processing, brewing, mono sodium amalgamate, biology and chemical industry, environmental protection etc. Our farm used galvanized steel grain bins are also applied for other kinds of industries because of its large capacity and low cost.