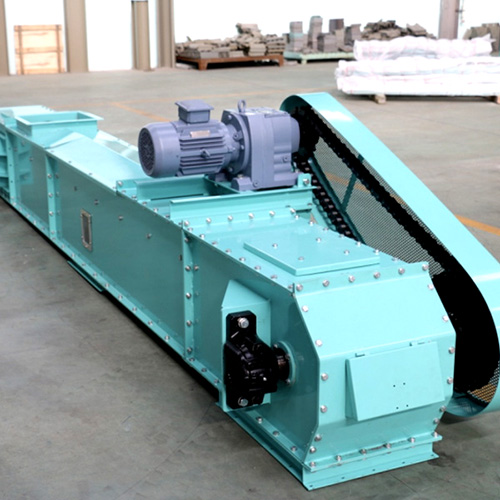

Drag conveyor (also called drag chain conveyor) is one of the commonly used material handing equipment for grain storage silos, it is a light enmasse conveyor which is widely applied for food or grain handling. The drag conveyor is a continuous conveying transportation equipment with a rectangular cross-section connected with the moving chain. Drag chain conveyor is widely used to transport the particles and powdered material horizontally, it also can be used for transport obliquely and vertically.

The drag conveyor does not produce dust and cause no environmental pollution because of the whole sealing of the closed trough, so it can improve the worker operating conditions and can’t cause food scatter when used in the outside. It is also free from weather conditions.Meanwhile, It is capable of executing both single point and multi-point feeding and discharging. In some conditions, it has some prominent advantages for the toxic, explosive, high temperature materials transportation. It can also be applied for flying material transportation to protect working conditions and prevent environment pollution.

High Quality Grain Drag Conveyor For Grain Storage Silos

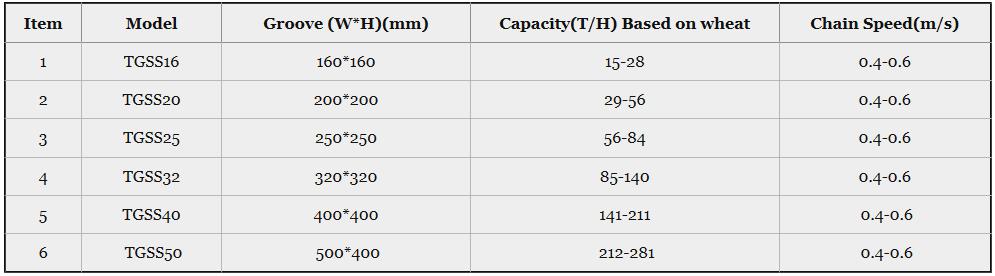

Specifications of Drag Conveyor

Features of Drag Conveyor

•High performance, easy to operate, easy to maintain

•Stable running, low noise and long service life

•Thread rod type takeup (tensioner) can be fitted at the tail so as to meet various conveying requirements

•Flexible for multi-point feeding and discharging

•Equipped with an alarming device for material blockage

•Devices for speed loss and chain breakage protection are optional

Drag Conveyor Applications

Drag conveyors are suitable for conveying bulk food, oil, feed and other bulk materials. They are widely used in sea port, dock, grain depot and the malt, flour, brewery, feed and chemical industries for horizontal bulk material conveying.

About Shelley Engineering

Shelley Engineering is the professional steel grain silos designer and manufacturer dedicated in supplying turn key grain storage and handling solutions to worldwide customers. We have more than 30 talented grain storage solutions experts and 9,000 square meters state-of-the-art factory. Our innovative, high-quality flat bottom silos, hopper bottom silos, powder silos, feed silos, bucket elevators, dust collectors and grain storage control system are integrated as a system to satisfy your grain storage requirements.

Shelley Engineering is not only manufacturing best quality grain storage products but also providing professional design and installation service. OEM, ODM, custom design and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.