The storage material of this project is biomass pellets, which breaks the traditional mode of ton bags or room-type storage in the biomass pellet industry. It adopts advanced hopper Silo complete equipment storage solutions, effectively utilizes warehouse land, saves land area, and reduces environmental pollution during the feeding and storage process. It helps customers solve the problem of complex employment, reduces the number of workers, and realizes the automated management and transportation of materials from storage, transportation, and production. It solves customers' pain points in one stop and brings long-term benefits to the company.

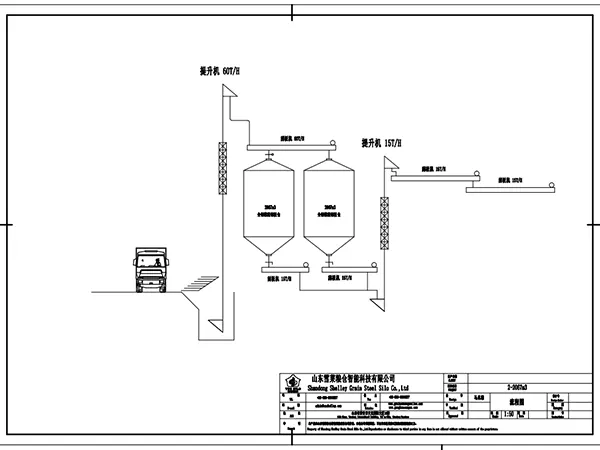

This project consists of 3-1,500 ton steel silos and supporting equipment: hydraulic flip unloading system, with an unloading output of 100 tons per hour, and supporting equipment consisting of lifting equipment, conveying equipment, ventilation system, grain temperature monitoring system, and intelligent electric control system. The surface of the conveying equipment and the steel silo body is all galvanized, which can prevent rust. The steel silo body is assembled with 275g/㎡ double-sided galvanized sheet. All the silo body bolts use 10.9-grade high-strength Dacromet galvanized bolts. The service life of the steel silo is more than 25 years.

The silo solution for this project is simple, elegant and practical. All electronically controlled intelligent control systems are adopted, which are convenient and fast, saving labor and increasing standby efficiency by 25%. It realizes the mechanization of grain in and out of the silo and saves labor costs.

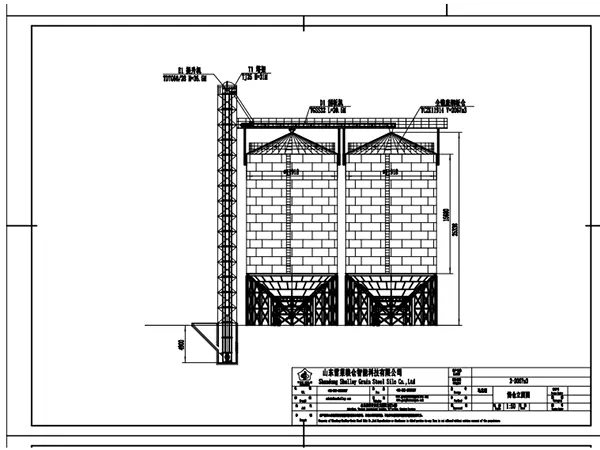

Model: 1500T steel silo

Volume: 2067m³

Diameter: 11.9m

Number of rings: 14

Silo height: 15.68m

Total height: 25.33m

Cone angle: 25°

The silo roof cover is made of δ1.0mm hot-dip galvanized plate, and domestic high-quality hot-dip galvanized plate is selected. Ventilation windows, manholes, and ladders are set on the silo roof. The hopper Silo roof is sealed with aviation glue and waterproof washers, and safety guardrails are set around the silo eaves.

Silo: The silo wall material is made of high-quality hot-dip galvanized coils from large steel mills. The double-sided galvanizing amount is 275g/㎡, and the final galvanized coating presents a continuous, smooth and uniform effect. The corrugated plate adopts automatic punching; the joints of the silo are sealed with aviation-grade waterproof adhesive strips; the columns and silo walls are connected with high-strength bolts with specially customized anti-oxidation films and special coatings.

After the project was processed in our factory, it was shipped to client’s site through logistics. After the goods arrived at the site, installation personnel would be sent to the project site to unload the truck and complete the installation and commissioning of the project. With the cooperation of both parties, the project was successfully installed and received praise from our client, who gave high praise our company and our on-site engineers.

The maximum storage capacity of a cone-bottom steel silo is 2,000 tons, which can be used in feed mills, flour mills, farms, wineries, national grain depots, grain trading companies, food processing plants, etc. Steel silos are equipped with supporting equipment, which can be configured with equipment such as warehousing, warehousing, ventilation, drying, temperature measurement, empty and full measurement according to the requirements of use, so as to achieve the purpose of safe grain storage. As steel silos have the advantages of small footprint, high degree of mechanization, labor saving, convenient installation and delivery, and easy automation, assembled steel silos have been widely used.

Shandong Shelley Grain Steel Silo Co., Ltd. is a leading domestic grain storage solution provider, dedicated to providing global customers with a one-stop service provider for grain storage and supporting solutions. It is a modern high-tech enterprise integrating the research and development, design, manufacturing, sales, installation and technical after-sales service of intelligent silos, intelligent environmental measurement and control equipment, automated control systems, and grain and oil processing equipment.

Founded in 2007, the company has complete hardware and software facilities and now has more than 60 invention patents and utility model patents. It has a dust-free workshop equipped with the most advanced fully automatic laser cutting machine, fully automatic corrugated plate roll forming machine, fully automatic silo roof cover production line, welding robot, CNC lathe, metal bending machine and automatic shearing machine, etc. The company has more than 30 professional designers and engineers, more than 300 factory directors, workshop directors, production dispatchers, skilled workers and installers; automated production effectively guarantees high-quality, high-precision and standardized production operations, and effectively meets the high-quality and timely delivery of projects.

The prefabricated steel silos produced by the company can have a single silo volume of 50 tons to 15,000 tons. The design service life of the silo is more than 25 years. Since the establishment of the company, the storage and supporting equipment produced by our company have established extensive cooperation with domestic customers with excellent product quality and good after-sales service. At the same time, they are exported to more than 63 countries and regions including Argentina, Australia, the United States, Chile, Cambodia, Ethiopia, Honduras, Iran, India, Indonesia, South Korea, Malaysia, Myanmar, Pakistan, South Africa, Sudan, Serbia, Thailand, Tanzania, Ukraine, Vietnam, Peru, New Zealand, Mexico, Philippines and Uganda, and have won wide acclaim from domestic and foreign customers.