In recent years, with the development of the breeding industry towards modernization, scale, and scientific development, large-scale breeding groups have continued to emerge. Domestically, represented by large groups such as Muyuan, Wens, and Zhengbang, pig farms are constantly expanding. This project is about the construction of the automated raw material storage and R&D center of ShanDong ShenJlA Fodder Co., Ltd.

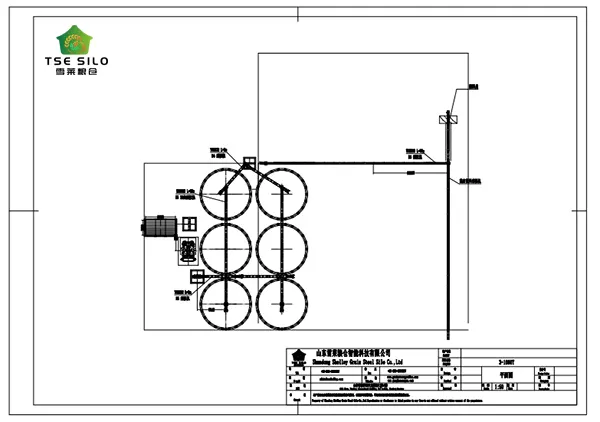

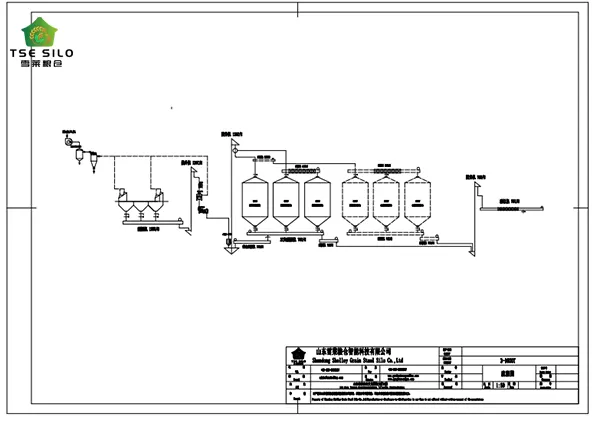

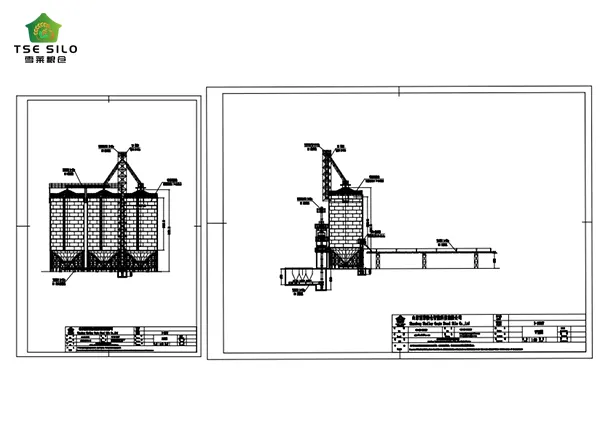

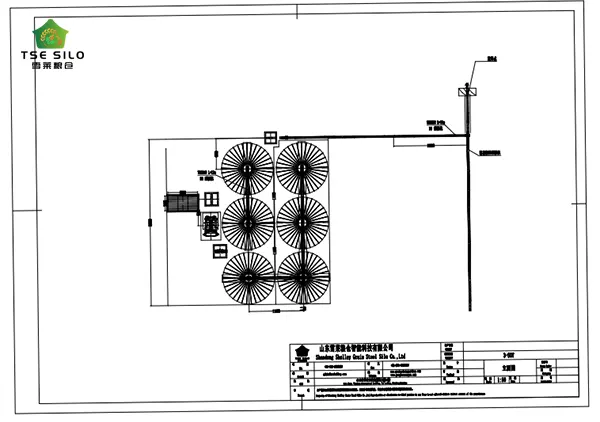

This project is a 3- 1000T corn steel silo. The process flow is as follows: The grain is first transported to the No. 1 elevator through the grain unloading pit, and then transported from the No. 1 elevator to the vibrating screen. It uses the principle of different sizes of materials and impurity particles to separate impurities and metals in the material, and transports them to the top through the elevator. With the electric distributor, the grain is transported to 3-1000T wheat silos respectively. The silo is equipped with ventilation and temperature measuring devices, which can monitor the changes in grain temperature and humidity in the silo in real time to achieve the purpose of safe grain storage.

1000 tons cone bottom steel silo is mainly used to store corn, wheat, rice and other grains and other granular materials. It has the advantages of high mechanization and long service life.

Volume: 1449m³

Diameter: 10m

Eave height: 15.66m

Total height: 24.4m

Roof angle: 25°.

The silo roof cover is made of δ1.0mm hot-dip galvanized plate, and domestic high-quality hot-dip galvanized plate is selected. Ventilation windows, manholes, and ladders are set on the silo roof. The silo roof is sealed with aviation glue and waterproof washers, and safety guardrails are set around the silo eaves.

Silo: The silo wall material is made of high-quality hot-dip galvanized coils from large steel mills. The double-sided galvanizing amount is 275g/㎡, and the final galvanized coating presents a continuous, smooth and uniform effect. The corrugated plate adopts automatic punching; the joints of the silo are sealed with aviation-grade waterproof adhesive strips; the columns and silo walls are connected with high-strength bolts with specially customized anti-oxidation films and special coatings.

The cone bottom of the silo is made entirely of steel structural parts, which is easy to discharge.

After the project was processed in our factory, it was shipped to client’s site through logistics. After the goods arrived at the site, installation personnel would be sent to the project site to unload the truck and complete the installation and commissioning of the project. With the cooperation of both parties, the project was successfully installed and received praise from our client, who gave high praise our company and our on-site engineers.

The application of steel cone bottom steel plate silo is very common in modern feed enterprises, but it has not been popularized in large-scale breeding enterprises. With the continuous large-scale development of breeding enterprises in the past two years, the steel cone bottom silo has also become a standard product for large pig farms, laying hen farms, cattle and sheep farms.

Shandong Shelley Grain Steel Silo Co., Ltd. has 18 years of experience in the design, production and manufacturing of steel plate silos, and has nearly 63 inventions and utility model patents for silos and supporting equipment. We have now exported to more than 63 countries and regions in North America, South America, Africa, Europe, the Middle East, etc. In the future, we will work hard towards intelligence, technology and full automation, and continue to strive to build a world-class steel plate silo enterprise.

People-oriented and service-oriented are the eternal pursuit of Shelley.