This project is the grain and oil turnover silo construction and intelligent upgrading project of Funing First Grain Depot Co., LTD., the construction of 2-1500T corn silo and supporting equipment,The role of steel silo in grain depot mainly includes the following aspects

1.To ensure the quality of grain: steel plate silo has good sealing, can effectively isolate the outside moisture, pests and pollutants, to prevent food moisture, mold and insect pests, so as to ensure the freshness and quality of food .

2. To improve storage efficiency: The design and construction of steel silo can be flexibly adjusted according to the specific site conditions and storage scale needs, and the space utilization rate is high. For example, the design of multi-ring steel silos can greatly increase the storage capacity. In addition, the fully sealed design of the steel silo can control the environment and reduce waste and loss .

3. To reduce maintenance costs: compared with traditional storage facilities, the construction and daily maintenance costs of steel silo are lower. The required materials and construction processes are relatively simple, and daily maintenance only requires regular inspections and simple maintenance.

4. Modern management: steel plate silo can be linked with temperature and humidity sensors, ventilation system and other intelligent equipment to achieve comprehensive monitoring and intelligent regulation of the silo environment, optimize the inventory management process, reduce waste and loss. In addition, steel silo can also carry out real-time monitoring and data interaction through the IoT, big data and other technologies to improve the scientific and effective supply chain management.

The project workflow is:

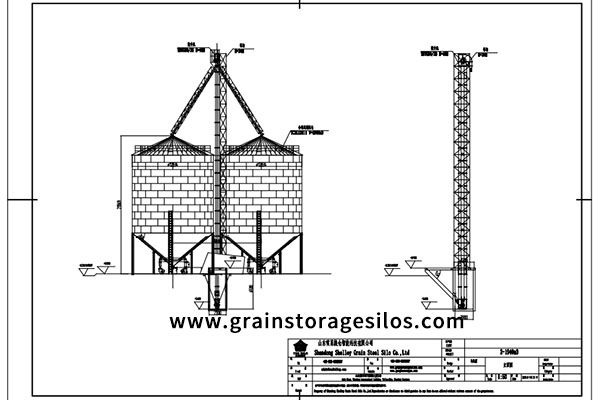

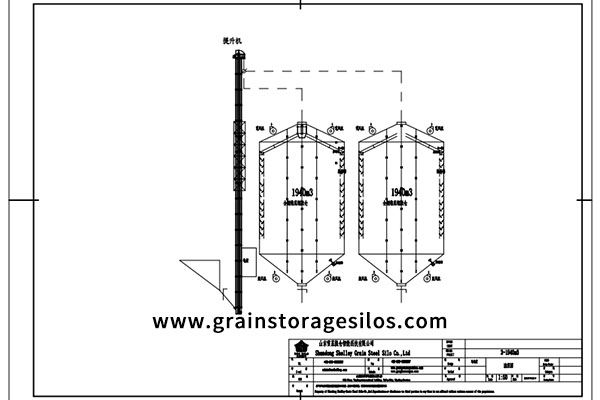

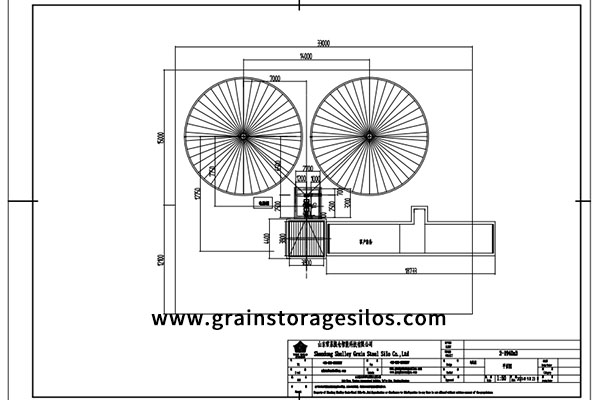

2-1500 tons of corn storage cone bottom steel silos are lined up, the tower is set in the center of the two silos, the grain is unloaded by hydraulic flapper, the material enters the grain unloading pit, and then is lifted up to the elevator, the elevator will transport the grain to the top with electric three-way distributor, and then the grain is transported to different steel silos. The silo is equipped with ventilation and temperature measuring device, It can detect the change of grain temperature and humidity in the silo in real time to achieve the role of safe grain storage. When the grain is discharged from the silo , the bottom drag conveyor will transport the grain to the designated position.

Design plan:

2-1500T hopper bottom steel silo parameters:

1500 tons of hopper bottom steel silo is mainly used to store corn, wheat, rice and other grain and other granular materials. It has the advantages of high degree of mechanization and long service life.

1500T cone bottom steel silo:

Volume:1940m³

Diameter: 12.8m

Eave height :12.32m

Total height :21.95m

Roof angle :25°

The top cover plate of the silo is δ1.0mm hot galvanized sheet, which is made of domestic high quality hot galvanized sheet. The roof of the silo is provided with natural ventilation window, manhole and ladder. The roof of the silo is sealed with aviation adhesive and waterproof washers. Safety guardrail is arranged around the eave of the silo.

Silo: The silo wall material is made of high-quality hot-dip galvanized coils from large steel mills. The double-sided galvanizing amount is 275g/㎡, and the final galvanized coating presents a continuous, smooth and uniform effect. The corrugated plate adopts automatic punching; the joints of the silo are sealed with aviation-grade waterproof adhesive strips; the columns and silo walls are connected with high-strength bolts with specially customized anti-oxidation films and special coatings.

The columns are connected to the silo wall using high-strength specially customized Dacromet galvanized bolts, without any welding points, thus avoiding the problem of corrosion on the silo wall due to welding.

The silo cone bottom is made of steel structural components, which is easy to discharge. This solution has high cost-effectiveness and added value, which saves equipment costs while reducing energy consumption during equipment operation. It can not only protect the safe storage of food, but also facilitate later maintenance.

Delivery and installation services

After the project was processed in our factory, it was shipped to client’s site through logistics. After the goods arrived at the site, installation personnel would be sent to the project site to unload the truck and complete the installation and commissioning of the project. With the cooperation of both parties, the project was successfully installed and received praise from our client, who gave high praise our company and our on-site engineers.

About Us

Shandong Shelley Grain Steel Silo Co., Ltd. is a leading domestic supplier of grain storage solutions, committed to providing one-stop service providers for grain storage and supporting solutions to global customers. It is a modern high-tech enterprise that integrates the research and development, design, manufacturing, sales, installation, and technical after-sales service of intelligent grain storage, intelligent environment measurement and control equipment, automation control systems, and grain and oil processing equipment.

The company was founded in 2007, hardware and software facilities are complete, now has more than 63 invention patents and utility model patents. The existing dust-free workshop is equipped with the most advanced automatic laser cutting machine, CNC lathe, metal bending machine and automatic shearing machine, etc. The company has a professional designer, engineer team of more than 30 people, factory director, workshop director, production scheduling, skilled workers and installation workers more than 300 people.

The prefabricated steel silos produced by the company can have a single storage capacity from 50 tons to 15,000 tons. The design service life of silo is more than 25 years. Since the establishment and development of the company, the warehousing and supporting equipment produced by our company, with excellent product quality and good after-sales service, has established extensive cooperation with domestic customers, and has been exported to Argentina, Australia, the United States, Chile, Cambodia, Ethiopia, Honduras, Iran, India, Indonesia, South Korea, Malaysia, Myanmar, Pakistan, South Africa. Sudan, Serbia, Thailand, Tanzania, Ukraine, Vietnam, Peru, New Zealand, Mexico, Philippines and Uganda and other more than 63 countries and regions, has won wide praise from domestic and foreign customers.