In the golden autumn season, overlooking Hanjiang Village, Hongguang Street, Mimou Town, Chengdu, from a high altitude, the crisscrossing field paths outline a picture of pastoral scenery, and 500 acres of high-standard farmland presents a golden harvest scene.In the compound grain and oil industrial park of "Tianfu Grain Silo", five silvery steel silos stand between heaven and earth, showing a magnificent momentum.These thermal insulation steel silos specially designed by Shandong Shelley Grain Steel Silo Co., Ltd. are built to support the "Tianfu Grain Silo Project".The operation of the project marks the completion of the last key link of the Tianfu grain silo project in Mimou Town, which realizes the automation, intelligence and mechanization of the whole industrial process from sowing, harvesting to grain drying and storage, and brings a new production mode to farmers.

This project consists of 1-3000 tons, 2-1000 tons and 2-500 tons silos with a total capacity of 6000 tons. The project silos are rich in type, convenient and highly intelligent, and all use PLC intelligent operation. Equipped with intelligent storage system, intelligent temperature control system, automatic warehouse system and intelligent ventilation data remote transmission of various advanced configurations.The steel silo body is assembled from 275g/㎡ double-sided galvanized sheet, and the bolts of the silo body are all 10.9 and 8.8 high strength Dacromet galvanized, which can ensure the service life of the steel silo for more than 25 years.

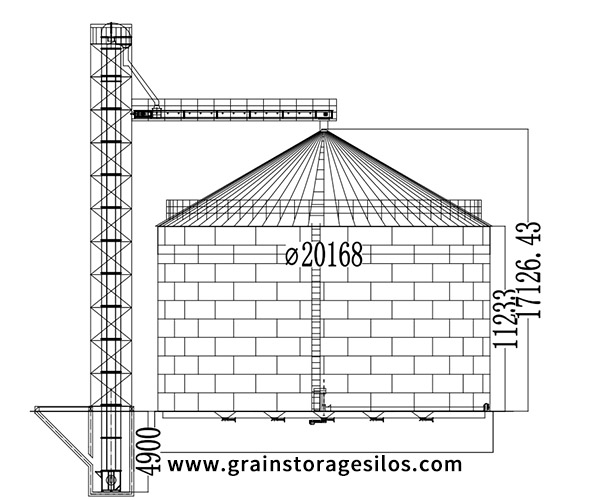

The specific parameters of 3000 ton steel silo are as follows:

1-3000T galvanized steel silo parameters

Model :TCK20110

Diameter :20.1m

Volume :4090m3

Eave height :11.23m

Total height :17.12m

Silo rings:10 rings

Thickness of galvanized coating:275g/m2

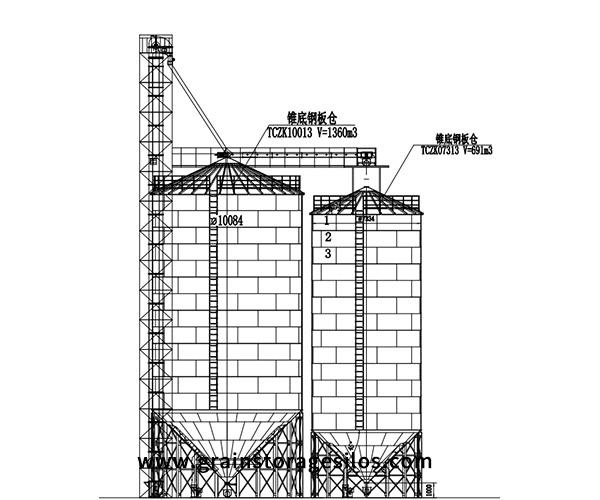

The specific parameters of the steel silo are as follows:

2-1000T galvanized steel silo parameters

Model :TCZK10013

Direct :10m

Volume :1360m3

Eave height :20.41m

Total height :22.85m

Silo ring:13 rings

Hopper Angle :45°

Thickness of galvanized coating:275g/m2

2-500T galvanized steel bin parameters

Model :TCZK07313

Diameter :7.3m

Volume :708m3

Eave height :18.76m

Total height :20.9mm

Silo ring:13 rings

Hopper Angle :45°

Thickness of galvanized coating:275g/m2

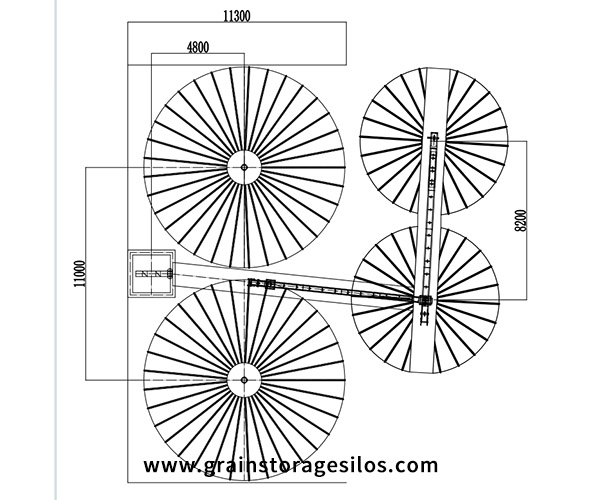

The rationality of the project plan:

First of all, the formulation of this project plan is based on the in-depth understanding and careful investigation of the customer's project site, combined with the site general layout, we have carried out careful optimization design. This solution not only performs well in terms of saving land occupation, but also significantly improves the practicality of operation, ensuring the efficient operation of the project.

Secondly, the combination of this scheme and drying center has the best effect. By optimizing the design, we have achieved the flexibility to store food for a long time and transfer it for a short time, thus effectively reducing the cost of storage and transfer, while reducing the reliance on labor.

Moreover, the entire process of the project has been electronically controlled and mechanized. This modern mode of operation is not only simple, efficient, and convenient, greatly improving the accuracy and speed of the operation, and bringing a new user experience.

In addition, our project programs also make a positive contribution to environmental protection and low carbon. It is fully in line with the development trend of new countryside, new agriculture and new agricultural machinery, reflecting our commitment to sustainable development and the importance of environmental protection.

As a mature storage solution, steel silo has a history of decades of development in the field of grain supporting. However, the combination of steel silos with the development trend of new agriculture, new rural areas and new agricultural machinery is still a relatively new attempt in the industry. We firmly believe that through cooperation with our customers, Shelley will be able to become a benchmark for agricultural development and create a new trend in rural cooperation.

In terms of installation, since the signing of the contract, Shandong Shelley has strictly complied with the terms of the contract to ensure the production schedule and quality. On April 15, 2024, our professional installation team officially entered the field to start the installation work. This team has more than 15 years of experience in the installation and construction of steel silos, among which the installation leader and project manager have more than 20 years of industry experience. Our operators are carefully trained by the company's professionals, they hold a variety of professional qualifications such as welding certificate, thermal cutting certificate and climbing certificate. We know that good installation is the second extension of product quality, therefore, to provide customers with quality and satisfactory service, is our unswerving pursuit.

We have always believed that good silos are made by Shelley. We sincerely welcome the majority of users to visit our company for inspection and guidance, and jointly witness Shelley's professionalism and innovation in the field of agricultural storage solutions.