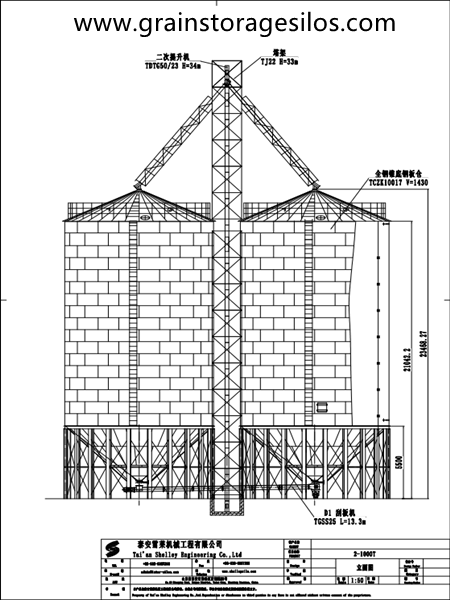

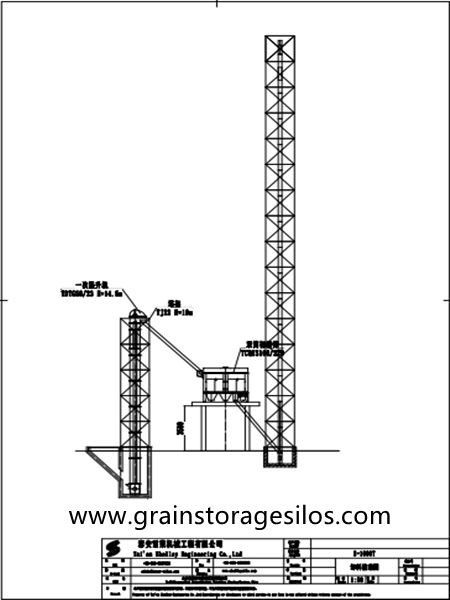

the grain enters the grain unloading pit, the bucket elevator vertically transports the material to the top, the electric two-way opens the valve, and the grain enters the two hopper bottom silos through the flow pipe.

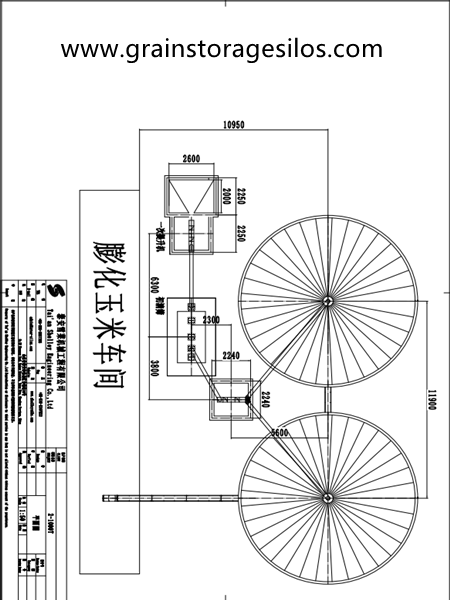

hopper bottom silo specification:

volume:1719m3

diameter:10m

eave height:21.042m

total height:23.468m

zinc coated:275g/m2

hopper bottom silos (also called cone bottom silos, hopper bottom storage bins, hopper bins) are?the steel silos with a cone bottom. hopper bottom silos are erected on the supporting structure to make the delicate products unloading easily through gravity. hopper silos have a smooth wall hopper transition with no steps or flanges to offer the cleanest product discharge from the silo. the stored products inside the silo are isolated from the ground, thereby preventing humidity and allowing the interconnection of silos through tapes, facilitating perfect extraction or dosage.

hopper bottom silos are widely applied for the storage of grains (sunflower seeds, soy, maize, sorghum, rice, industrial products and other products, etc) and feed pellets for animal, poultry and fish that require special storage conditions. they can also provide temporary storage of wet grain as part of a grain drying plant and other buffer bin applications in silo plants. they are widely used in poultry farm, rice mill, flour mill, soybean-oil mill, animal feed mill plant and brewery plant.