Grain steel silos occupy an important position in the grain storage industry due to their small footprint and large storage capacity. However, the construction of grain steel silos requires very high technical standards, especially in wind-resistant design, which has very strict standards. This is mainly because the larger the storage capacity, the higher the height and the higher the wind resistance level. Therefore, large grain steel silos have very high wind resistance requirements from design and construction to later operation. Today, we will explain the wind resistance standards and measures adopted for grain steel silos from design to application.

1. Structural Strength and Stability

This is the foundation for resisting strong winds, just like a person's skeleton. Only a strong skeleton can support the stability of our entire body. The same applies to grain steel silos; the steel used must meet the standards.

1.1. Silo Shell Itself

- Material Strength: The galvanized steel plates or color-coated plates used in steel silos have high tensile strength.

- Circumferential Stiffening Ribs (Rolled Edge Ribs): This is one of the most critical design features. During the steel plate rolling process, dense, regularly spaced annular ribs are rolled out. These stiffening ribs significantly improve the circumferential stiffness and longitudinal stability of the silo wall, much like putting many tight hoops on a soda can, making it less susceptible to crushing or twisting. Under wind loads, they effectively prevent local buckling (denting deformation) of the silo wall.

- Vertical stiffening ribs: For large steel silos, large vertical stiffening ribs are usually welded to the outer side of the silo wall. Working together with the circumferential stiffening ribs, they form a strong spatial grid support system, further increasing overall stability.

1.2. Reasonable structural form

- Conical roof: Most steel silos use a conical roof. This streamlined design effectively guides wind to slide across the sides of the silo roof, reducing the direct impact and upward force of the wind on the roof.

- Height-to-diameter ratio: The ratio of the silo's height to its diameter is controlled during the design phase. A reasonable height-to-diameter ratio ensures the stability of the structure under wind loads, avoiding a "top-heavy" or excessively slender structure that is prone to instability.

2. Key Considerations for Wind-Resistant Design of Grain Steel Silos

When designing steel silos, Shelley Storage first analyzes local weather and geological conditions to provide a cost-effective design solution for the client. Wind-resistant design is not merely about calculating wind loads, but a process that permeates the entire process from structural selection and calculation analysis to detailed construction. Its core is accurately calculating wind loads and ensuring that the load is effectively transferred to the foundation.

2.1. Design Standards and Specifications

The design must comply with international and industry standards; this is the most basic and important requirement.

Main Specifications:

- Code for Design of Grain Steel Silos (GB 50322), Code for Design of Building Structures (GB 50009), Standard for Design of Steel Structures (GB 50017).

Basic Wind Load Parameters:

- Basic Wind Pressure: Determined based on the 50-year return period wind pressure value (100-year return period for important silos).

- Wind Pressure Height Variation Coefficient: Considers the influence of silo height on wind pressure.

- Wind Load Shape Coefficient: This is crucial! Steel silos have circular cross-sections, and their shape coefficient differs from that of square buildings, as clearly defined in the specifications. Attention must be paid to the combination of internal and external pressures.

- Wind Vibration Coefficient: For steel silos with greater height and longer natural periods, the pulsating effect of wind pressure must be considered, and the wind vibration coefficient must be calculated.

2.2. Wind-Resistant Design of the Structural System

Silo Wall Structure

- Buckling Stability: Steel silo walls are thin, and local buckling may occur under wind pressure (like a crushed can). This is a critical design consideration.

- Reinforcing Ribs (Ring Beams): By installing vertical stiffening ribs and horizontal ring beams at intervals on the outer side of the silo wall, the overall stiffness and buckling resistance of the silo wall are greatly improved. The spacing and dimensions of the ring beams require rigorous calculation.

- Thickness Distribution: Wind pressure increases with height; therefore, the steel plate thickness of the silo wall is usually distributed in a "thicker at the bottom, thinner at the top" pattern, which is both economical and safe.

Overall Stability:

- Overturning Moment: Wind loads generate a significant overturning moment, attempting to topple the silo.

- Overturning Resistance Design: Resisted through sufficient self-weight and foundation design. The connection between the silo and the foundation must be rigid to effectively transfer bending moments.

- Foundation Design: The foundation must have sufficient depth, dimensions, and weight to ensure resistance to slippage and overturning. For silo clusters, the foundations may be integrated and work together.

2.3. Special Considerations for Wind Load Calculation

- Cluster Effect: When multiple silos are arranged side-by-side, airflow between them can interfere with each other, leading to a significant increase in local wind pressure in some silos (usually located in corners or gaps). The wind load amplification factor must be considered in the design.

- Vacuum Effect: For steel silos supported by pillars, wind can pass through the spaces between the pillars, causing complex effects on the silo floor structure, requiring separate calculation.

- Attached Wind Loads: Accessories such as stairs, platforms, vents, and dust collectors on the silo roof will generate additional wind loads and may cause localized stress concentrations. These need to be considered in the model or locally reinforced.

2.4 Precise Aerodynamic Design

- Wind Caps: Ventilation openings on the silo roof are usually equipped with specialized wind caps. These not only protect against rain, but their special shape also prevents strong winds from generating significant negative pressure (suction) at the ventilation openings, thus preventing the silo roof from being "sucked" up and damaged.

- Wind Baffles: In areas with particularly complex wind conditions, wind baffles may be installed around the silo roof. These can alter the airflow pattern at the edge of the silo roof, preventing the formation of separation vortices, thereby significantly reducing wind-induced vibration and localized wind pressure.

3. Related Considerations (Design, Construction, and Maintenance)

Many problems arise not only in the design phase, but also during construction and operation.

3.1. Considerations in the Design Phase

- Accurate Geological Survey: Foundation design relies entirely on accurate geological reports. Foundation bearing capacity and settlement calculations must meet the required specifications.

- Load Combinations: Wind loads do not act in isolation; they must be combined with grain loads (full silo, half-silo, eccentric unloading), snow loads, seismic loads, and temperature loads to achieve the most unfavorable combination.

- Silo Wall to Foundation Connection: This is where stress is most concentrated; the strength and stiffness of welded or bolted connections must be guaranteed.

- Stiffening Rib to Silo Wall Connection: The strength and spacing of welds or connectors must ensure effective transfer of wind loads to the stiffening ribs.

- Finite Element Analysis: For large, complex, or special-shaped steel silos, it is strongly recommended to use finite element analysis (FEA) for detailed design, simulating stress, strain, and buckling modes under wind loads to identify weak points.

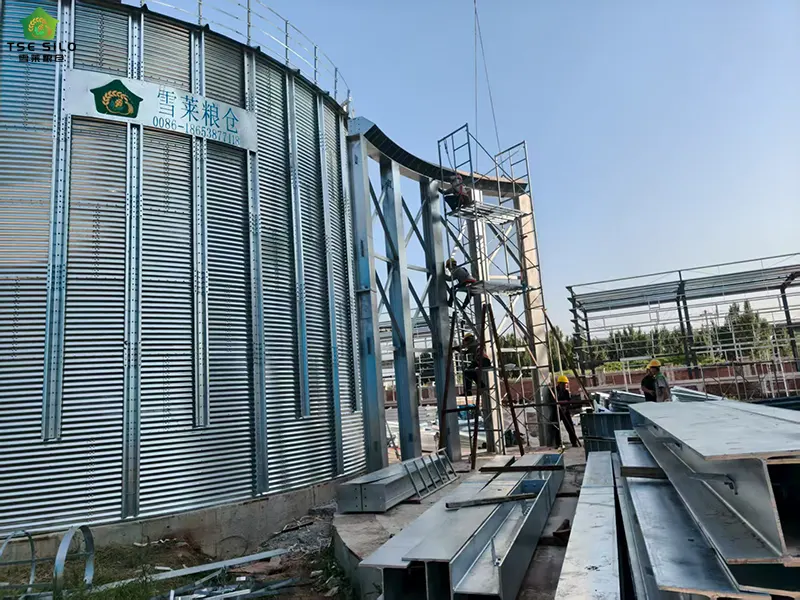

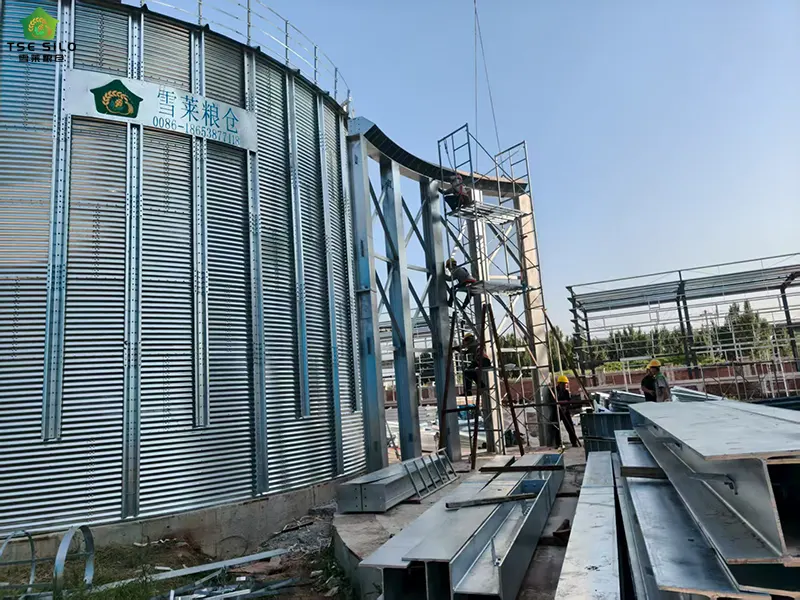

3.2. Construction Phase Precautions

- Material Quality: The material and thickness of steel plates, profiles, and connectors must meet design requirements.

- Welding Quality: Welds are the lifeline of the structure. Welding processes must be strictly controlled, and non-destructive testing (such as ultrasonic and X-ray) must be performed to ensure the absence of cracks, incomplete penetration, and other defects.

- Installation Accuracy: The verticality of the silo, the flatness of the ring beam, and the verticality of the stiffening ribs must all be controlled within the allowable error range. Any initial defects will significantly reduce the structural stability and load-bearing capacity.

- Corrosion Protection: The anti-corrosion coating at welded joints and damaged areas must be repaired according to design requirements to prevent thinning of the plates due to corrosion, thereby reducing wind resistance.

4. Core Concepts

- "Guiding": Utilizing the streamlined design of the cylinder and conical top, wind is guided smoothly, reducing wind pressure.

- "Resisting": Utilizing the strong grid formed by circumferential and vertical stiffening ribs, wind pressure is resisted and distributed, preventing local instability.

- "Anchoring": High-strength anchor bolts and a massive foundation firmly transfer the overturning force generated by the enormous wind load to the ground.

5. Daily Inspection and Maintenance (Ensuring Structural Integrity)

This is the most basic and core operational wind-resistant measure, aimed at ensuring that the wind-resistant structural system is always in good condition.

Anchoring System Inspection

- Anchor Bolts: Regularly inspect anchor bolts for looseness, corrosion, or breakage. Corrosion reduces bolt cross-section and significantly decreases strength. If found, tighten or replace immediately.

- Foundation: Inspect foundation concrete for cracks, spalling, or settlement. Uneven foundation settlement alters structural stress and greatly weakens wind resistance.

Storage Structure Inspection

- Storage Walls: Inspect silo wall steel plates, especially the lower section and high-stress areas, for corrosion, deformation, or damage. Even small holes can cause tearing in strong winds.

- Stiffening Ribs: Inspect circumferential and vertical stiffening ribs for cracks, weld detachment, or deformation. These are the "ribs" resisting wind pressure, and their integrity is crucial.

- Welds and Connections: Inspect all major welds and high-strength bolt connections for cracks or looseness.

Storage Roof and Ancillary Facilities Inspection

- Storage Roof: Inspect the conical roof cover for secure fixing and proper sealing.

- Windproof Caps: Ensure the windproof caps of the vents move freely, are not frozen by dust, debris, or ice, and are functioning properly.

- Doors, Windows, and Openings: Check that all doors, windows, and inspection openings can be completely and tightly closed, and that their locking devices are effective. This is the most prone to problems during operation.

6. Standardized Operation and Management (Eliminating Human Risk)

Many cases are caused by improper operation by personnel, leading to malfunctions in wind-resistant facilities and damage to steel silos from strong winds. Therefore, we must strictly follow operating procedures in daily operations and avoid negligence that could lead to serious consequences.

Door and Window Management

- Strong Wind Weather Guidelines: Upon receiving a strong wind warning, immediately ensure that all doors, windows, inspection openings, and vents are completely closed and locked. This is the simplest, most effective, yet most easily overlooked measure. Even a small open doorway can disrupt the streamlined shape of the silo, creating internal wind pressure and causing a superposition of internal and external pressures, which can easily tear the silo.

- Daily Habits: Even in windless weather, develop the habit of closing all openings after operation.

Surrounding Environment Management

- Clean up debris: Keep the silo roof and surrounding platform clean, free of any loose debris (such as tools, packaging materials, and waste). These items can become projectiles in strong winds, impacting the silo walls and causing damage.

- Inspect auxiliary structures: Ensure that ladders, platforms, conveyor bridges, and other auxiliary structures are securely connected to the silo body. These components are also prone to vibration or damage in wind.

Material Loading and Storage Management

- Avoid eccentric loading: Maintain a uniform distribution of materials within the silo as much as possible. Long-term eccentric loading can cause initial stress and deformation in the silo body, weakening its overall stability and making it less resistant to wind.

- Monitor material clumping: For materials prone to clumping, the sudden collapse of large material arches or wall-mounted materials can cause asymmetrical impacts on the silo walls, affecting structural safety.

7. Monitoring and Early Warning (Proactive Defense)

Establish a meteorological early warning mechanism

- Establish contact with the local meteorological department or use a weather app to closely monitor early warning information for extreme weather such as strong winds and typhoons.

- Establish an internal high-wind warning response process, clearly defining the specific measures to be taken and the responsible personnel involved upon receiving warnings of different levels (e.g., blue, yellow, orange, red).

Regular Professional Inspections

- Hiring a professional organization to conduct comprehensive safety inspections of the steel silos regularly (e.g., every 1-2 years), including using professional instruments to measure bolt preload, steel plate thickness, weld quality, etc., and issuing authoritative inspection reports and maintenance recommendations.

8. Emergency Preparedness (Better Thing Than Bad)

Develop a typhoon emergency plan

- The plan should include: personnel assignments, evacuation routes, emergency reinforcement procedures, and post-disaster inspection steps.

Prepare emergency supplies

- Such as wire ropes, chain hoists, large tarpaulins, emergency lighting, communication equipment, etc., for unforeseen circumstances. For particularly important silos, it may even be necessary to pre-install anchor points for windproof cables.

Conclusion

Wind resistance is one of the most crucial indicators for the normal operation of grain steel silos. Inadequate wind resistance can easily cause devastating damage in severe weather. To ensure food security, steel silos must be designed and constructed strictly according to standards; negligence in any (link/step) can lead to catastrophic consequences. Therefore, qualified professional units and personnel must conduct comprehensive quality control from design to operation and maintenance to ensure the absolute safety of steel silos under strong winds. Shelley Storage has professional designers and an experienced construction team, and possesses its own design philosophy regarding wind resistance standards for steel silos. For related inquiries, please contact us.

Written by

Shandong Shelley Grain Steel Silo Co., Ltd

Editor Jin

WhatsApp : +86-18653877118

Email : shelley@cnshelley.com