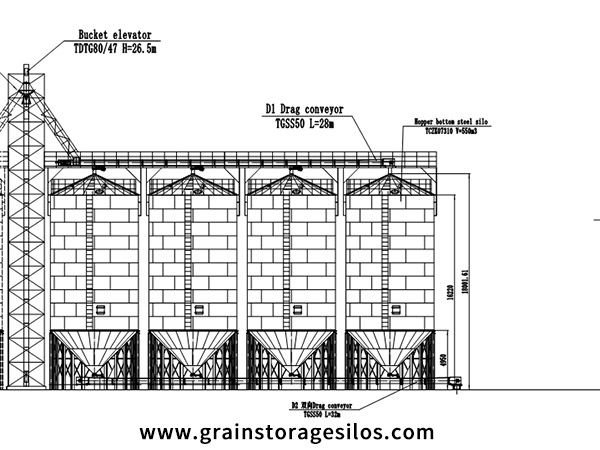

Grain hopper bottom silo (also called grain conical cone bottom silo) are successfully set up in Canada. This is a silo project includes 4 sets of grain silos plus the 200tph bucket elevator and 200tph conveyors ; In this grain silo project ,the customer will have the corn/beans/wheat to be transported from other place to the silo site , unloading the corn/beans/wheat above the weighing scale, then transport them by the 200tph drag chain conveyor under then scale; sending the grains to the 200tph bucket elevator , then lifting them to the top of the grain silos , using another drag conveyor to feed the grains into 4 silos one by one;

And if necessary, the drag conveyor under the grain hopper bottom silo can transport the grains to the workshop which located against the elevator, so this drag conveyor can run by 2 directions!

Hopper bottom silo (also called cone bottom silo ) is a kind of commercial silos which is widely used for farmers or grain traders. Because it is easy to discharge the grains from the silo without the equipments or the labors.

In This project, the grain silo cone is 45 degree and the silo volume is 550m3 each with hopper silo diameter of 7.3m;

TSE silo company can produce the bucket elevator from 5tph to 300tph; In this project, the grain bucket elevator is 200tph; It is a kind of HDPE elevator bucket fixing on the rubber belt, which has the long service life.

The TSE grain elevator motors specially designed according to the Canada standard. 600V, 50HZ, CSA certificate for the elevator motors and gear box is available,

The drag chain conveyor is the most shinning point in this silo system .200tph with 2 transport directions is very specially made for the customer needs, using one conveyor instead of 2 can save basic cost for the customers at the same time saving the power cost in the future.

The motor of the drag conveyor is 37kw, 600v, 50 Hz with CSA certificate;

The chain of the drag conveyor is made of manganese steel with one time mould production, it is high yield and tensile. There are always having the HDPE drags on each wing of the chain, which helps the wings to increase the anti-wearing ability for long time use;

Customer might have one question, how do I know the silo is full or not ? empty or not ?

Don’t worry, there are high-low leveling indicators fixed at the top & last ring of the grain silo body . it is a kind of mechanical sensor which can send signal to the power box to show if there are grains around the sensor or not ;

If customers want to know more exactly how many tons of the grain inside each hopper silos, TSE also have the device called grain silo weighing inspection system, it has 2% accuracy.

For the grain security storage, TSE provides the temperature & moisture monitoring system (also called grain temperature and moisture testing sensor) to help the customers get data every minute from inside and outside of each grain hopper bottom silo.It shows the temperature of the grain around the sensor , and the moisture of the air inside and outside the silo. The customer can know the grains condition by reading the date sheet;

In this grain silo system, there is no cleaner, but TSE can provide with the highly quality low cost automatic cleaning system, includes the drum cleaner or the vibrating cleaners , cyclone, air shutters, Impulse dedustors with capacity from 5tph to 150tph;

There is the ventilation system, includes the ventilation blowers, ventilion suctions fans and ventilation pipelines in this grain silo project;

This is the very useful and commercial equipments for the whole grain silo and elevator system;

Once the customers find the high temperature happens inside the grain silo , he can turn on the blower and fans .

Or TSE can provide you with the fully automatically sensor system for testing the temperature and moisture , then if there is high temperature or moisture alarm, the blower and fans can start working automatically , all it will be controlled by the PLC system.

For the Canada hopper bottom silo and elevator project, TSE designed the power control panel and cables according to Canada standard.

TSE can provide customers with the very normal control panel with button, at the same time, TSE provides the PLC system with the high and advanced technology;

4 sets of hopper bottom silos , 2 sets of drag chain conveyors , 1 set of the grain bucket elevators, elevator tower, drag conveyor catwalk, ventilation blower system, temperature & moisture monitoring system are the main supplying scope of this grain silo project , it took 2 months for designing and producing in TSE company; TSE grain silo company always offer the best and fasted delivery to the customers;

TSE send 4 technical workers to CANADA for setting up the whole grain silo system, it took them 100days to complete this project with any extra labors; Of course , if more workers to do this silo and elevator project together , it will be much faster.

TSE CAN PROVIDE THE BEST QUALLITY, LOW COST GRAIN SILO AND ELEVATOR CONVEYOR SYSTEM

TSE CAN PROVIDE THE BEST DELIVERY FOR THE GRAIN SILO & ELEVATOR AND CONVEYORS

TSE CAN PROVIDE THE HIGH SKILLED TECHNICAN TO DO THE INSTALLATION OR SUPERVISION FOR THE GRAIN SILO & ELEVATOR AND CONVEYORS.

TSE CAN RPOVIDE THE CUSTOMERS 24HOURS 7 DAYS ON LINE AFGTER SALES SERVICES ALL OVER THE WORLD.